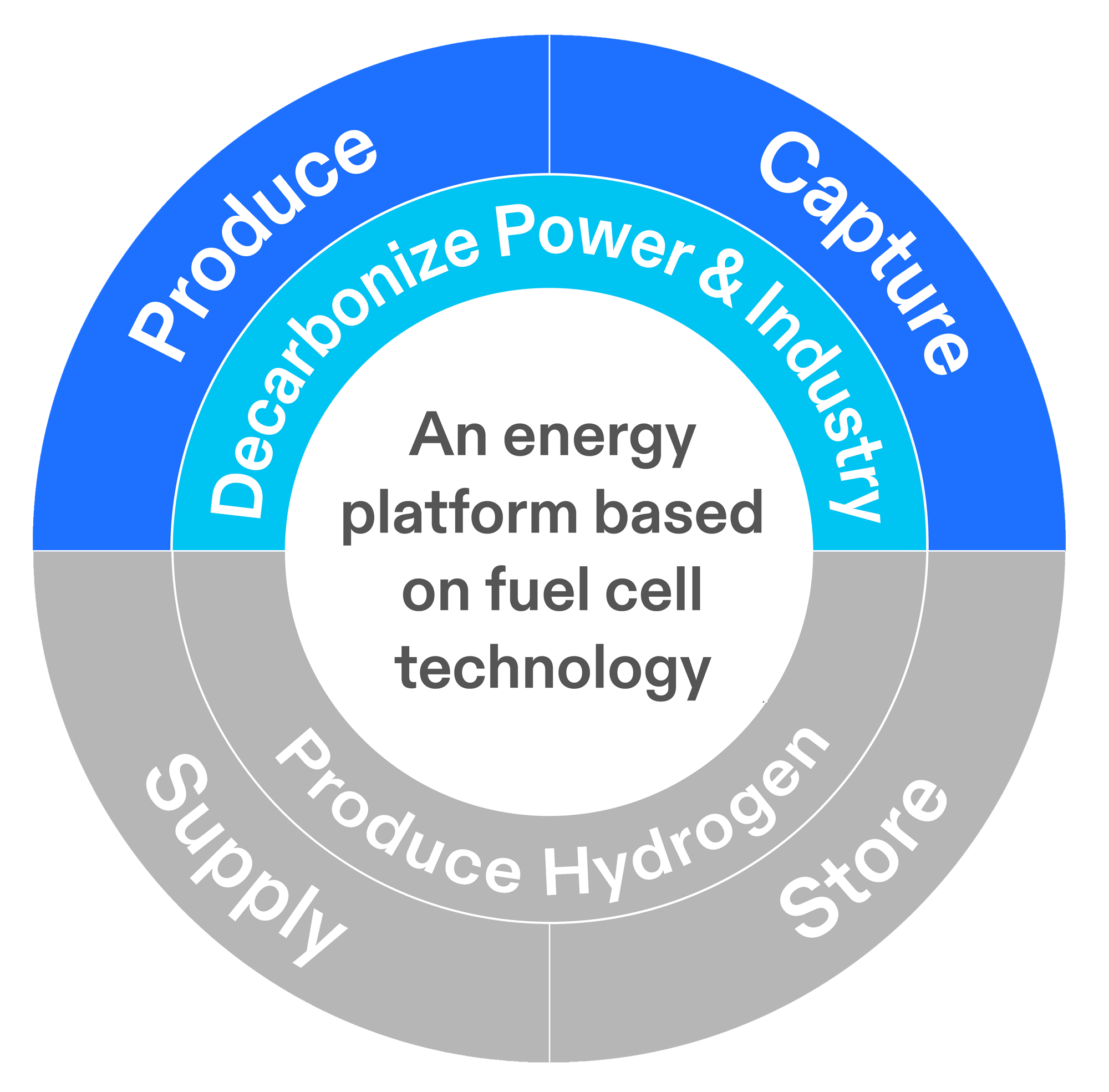

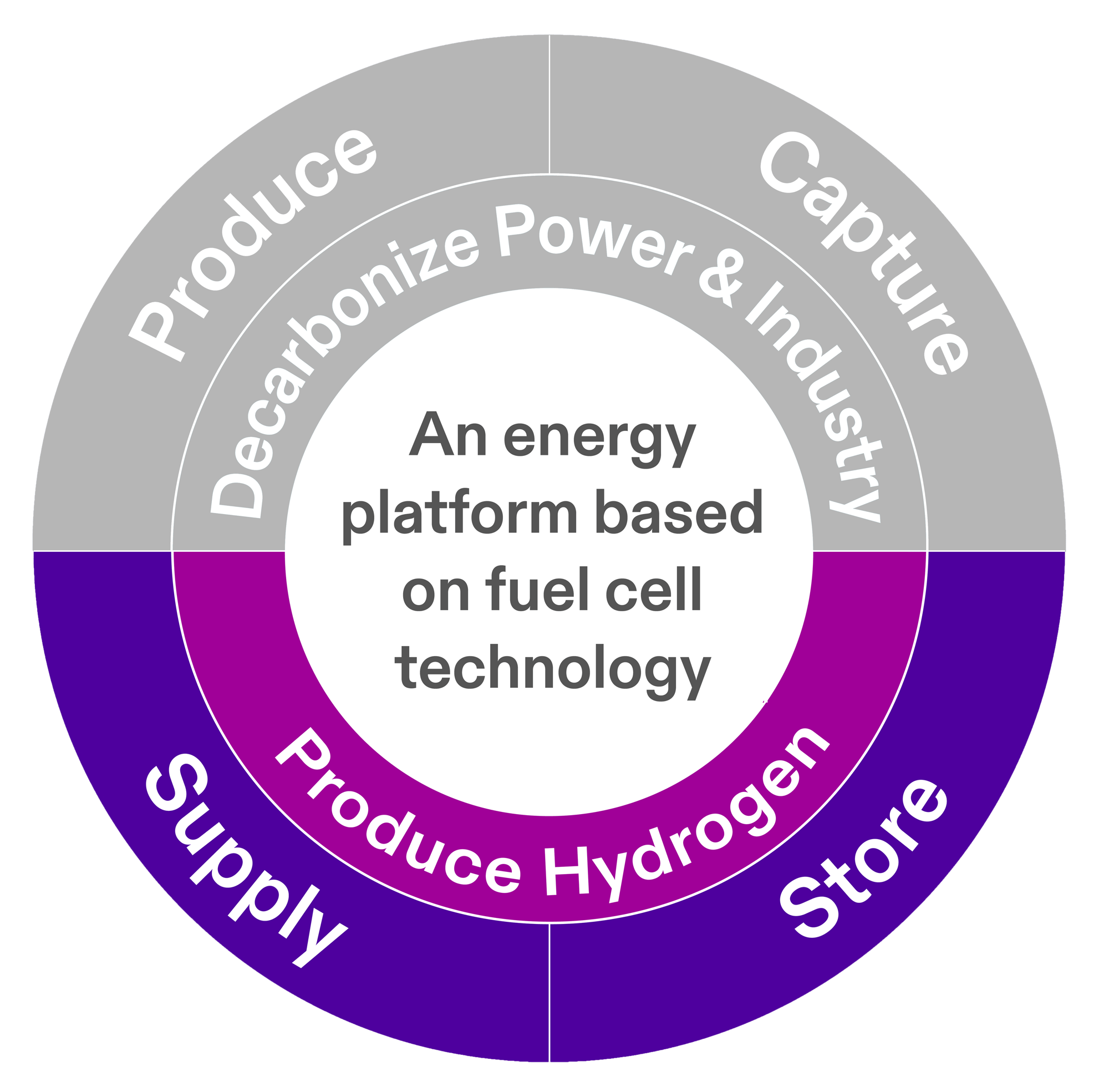

Everyone's journey to net-zero is unique, but is it possible to produce scalable clean energy from many different sources? With our platform, the answer is yes. We help organizations around the world reimagine their specific energy needs while staying true to their sustainability commitments. Together, we can avoid harmful emissions as the world transitions to lower carbon energy.

We believe in a world where everyone can produce low to zero carbon power. Our platforms can provide flexible paths to net-zero in realistic and achievable ways.

We envision a practical journey to net-zero that compliments both new and existing infrastructure. Our platforms can enable the energy transition by producing hydrogen and storing it for when it's needed.

FuelCell Energy's 2023 Sustainability Report is now available. Learn more