In today's energy market, the ability to operate on a variety of fuels provides businesses with critical flexibility to adapt to fluctuating prices and availability. By leveraging multiple fuel sources, companies can enhance their energy resilience and mitigate the risks associated with single fuel dependence.

Carbonate electrolytes are key to the system’s fuel flexibility

Carbonate fuel cells are named after their electrolyte, which is a layer inside each cell made of carbonates. The carbonate electrolyte allows the fuel cell to generate power from hydrocarbon fuels like natural gas, biogas, anaerobic digester gas, and even methane released from landfills and mining operations.

Inside the fuel cell modules, methane-based fuels (CH4) are steam-reformed into hydrogen (H2) and carbon dioxide (CO2). Ions in the electrolyte move between the fuel and air electrodes to keep the charge neutral between the electrodes as they produce and consume electrons. The isolated carbonate ions filter through the electrolytes in each cell.

.png?width=10668&height=3451&name=how%20fuel%20cell%20works_2_2560%20(1).png)

The fuel flexible system is capable of operating on natural gas, biogas, and natural gas/H2 blends of up to 50% H2. The system produces heat that can be used to generate hot water, high-pressure steam, or chilled water to increase overall efficiency.

Superior performance when operating on anaerobic digester gas

Anaerobic digester gas is a by-product of anaerobic digestion, a process in which bacteria break down complex organic wastes, resulting in the production of methane and CO2. One common fuel used by carbonate fuel cells is biogas from wastewater treatment facilities. FuelCell Energy’s carbonate systems are designed to thrive when generating electricity and heat from anaerobic digester gas. Heat from the fuel cells can be used for the anaerobic digestion process.

![]()

Wastewater treatment plants typically process sludge using anaerobic digesters, which produce methane gas (60%) and carbon dioxide (40%), along with other contaminants. While carbon dioxide may pose a challenge to other energy generation technologies, FuelCell Energy’s carbonate electrolyte uses it as a reactant inside the fuel cell to have a positive impact on voltage. This allows FuelCell Energy’s systems to operate at full power directly off the 60/40 mix typically found in ADG, without going through the costly process of upgrading it to pipeline quality.

FuelCell Energy’s proprietary fuel treatment technology

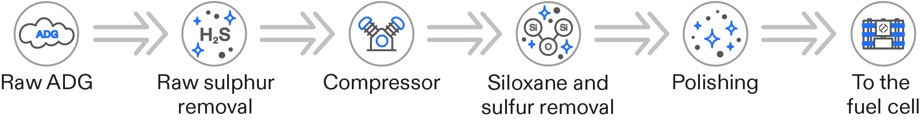

The municipal sewage processed at wastewater treatment plants contains contaminants like siloxanes and sulfur compounds. Siloxanes are introduced through various personal care items, such as hair products and waterproofing chemicals, while sulfur compounds are formed during the digestion process.

FuelCell Energy has developed a proprietary fuel treatment system that can effectively remove these siloxanes and sulfur compounds, ensuring that the fuel cells can run directly on the 60% methane and 40% carbon dioxide mixture produced by the digesters. This system not only prevents the contaminants from affecting the performance of the fuel cells but also offers a reliable and efficient solution for direct use of biogas from wastewater treatment plants.

Dual-fuel capabilities to meet real-world fluctuations

FuelCell Energy’s carbonate fuel cells can operate on a mix of on-site biogas and natural gas, maintaining output even during biogas fluctuations. The fuel blending option allows real-time mixing of primary and secondary fuel sources, (natural gas is typically the secondary source). This option supplements the primary gas when its production is limited and permits a complete switch to the secondary source if necessary. This flexibility is beneficial for applications with intermittent primary gas supplies. Wastewater treatment plants and breweries have benefited from FuelCell Energy’s dual-fuel capabilities, combining natural gas with anaerobic digester gas from their operations.

Future-ready design can operate on blends of natural gas and hydrogen

Fuel cell technology can run off fuels like natural gas today and switch to cleaner alternatives like hydrogen as they become more available. FuelCell Energy’s carbonate fuel cell systems can operate on blends of natural gas and hydrogen, with up to 50% hydrogen. Fuel flexibility provides adaptability in the event of market price fluctuations, continuity during supply disruptions, and long-term compatibility with existing infrastructure.

Contact us today to learn more about our carbonate fuel cell systems.